Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Tubular Screw Conveyor Equipment features a fully sealed tubular structure, effectively preventing spillage and dust generation. It is suitable for conveying powders, granules, and both small and large materials. Available in custom carbon steel, stainless steel, or polypropylene, the equipment is corrosion-resistant and abrasive-resistant to various materials and supports flexible conveying angles from 0 to 90°. The Tubular Screw Conveyor boasts a compact structure, a small footprint, and stable conveying efficiency, meeting the needs of enclosed conveying of powders and directional conveying of granular materials. The tubular diameter and length can be adjusted to meet your needs, providing a clean, high-speed, and customized material conveying solution for your production process.

Based on our customers' production needs, we offer various types of Tubular Screw Conveyor Equipment. These systems offer leak-proof conveying, adaptability to a variety of materials, flexible conveying angles, and suitability for a wide range of industries, providing efficient and clean conveying solutions for your production.

Double-head spiral tube screw conveyor: The double-head spiral tube screw conveyor is equipped with a discharge port and a feed port at both ends of the spiral tube, which can realize material feeding and discharging at both ends at the same time, and is suitable for material conveying with a certain rotation angle. and occasions of different heights.

Single-head spiral tube screw conveyor: Single-head spiral tube screw conveyor usually has only one inlet and one outlet, which is suitable for long-distance conveying of materials.

Stainless steel tubular screw conveyor: The stainless steel tubular screw conveyor has the characteristics of strong toughness, strong corrosion resistance, easy cleaning, and high temperature resistance, and is suitable for conveying high temperature, corrosive and easily adsorbed materials.

Carbon steel pipe screw conveyor: carbon steel pipe screw conveyor has the advantages of low cost and long conveying distance, and is suitable for small and medium-sized enterprises and industrial fields that do not require special requirements.

The fully sealed structure of the Tubular Screw Conveyor Equipment prevents dust and leakage, making it suitable for powdered and granular materials. Available corrosion-resistant materials offer flexible conveying angles from 0-90°, a compact footprint, stable efficiency, and reduced material contamination.

Excellent sealing performance: fully enclosed pipeline design effectively prevents dust spillage and material contamination, suitable for the transportation of toxic and hazardous materials

Flexible configuration scheme: supports horizontal, inclined (≤30°) or vertical installation, and can be connected in multiple sections in series to achieve long-distance transportation.

Wide material adaptability: can transport powdered, granular, small block materials, semi-solid materials with certain viscosity, and high temperature (≤200℃) or corrosive materials.

Carbon steel tubular screw conveyors have readily available raw materials and are low-cost. They also offer excellent rigidity and load-bearing capacity, making them suitable for conveying hard materials in conventional dry working conditions. Stainless steel versions are resistant to acid, alkali, and moisture, are easy to clean, and can be used in high-temperature and high-humidity environments, making them suitable for many special scenarios.

Carbon steel tubular screw conveyors: Their core advantages lie in high cost-effectiveness and strong structural performance. Raw materials are readily available, resulting in low manufacturing costs, making them suitable for users with limited budgets. Furthermore, the material offers strong rigidity and excellent load-bearing capacity, withstanding significant material impact and conveying pressure. It is suitable for conveying large, hard materials such as ore crushing and coal.

Stainless steel tubular screw conveyors: Their outstanding advantages are excellent corrosion resistance and wide environmental adaptability. Containing alloying elements such as chromium and nickel, they are resistant to corrosive environments such as acidic, alkaline, and humid environments, making them suitable for conveying acidic and alkaline powders in the chemical industry and aqueous materials in the food industry. Their smooth, easy-to-clean surface, free of rust and impurities, meets the hygiene standards of the food and pharmaceutical industries, preventing material contamination.

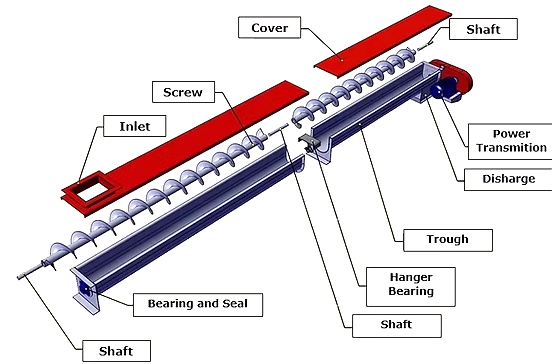

The core components of a Tubular Screw Conveyor Equipment include the tubular casing, screw blades, drive mechanism, inlet and outlet ports, and bearing assembly. These components work together to ensure a sealed and stable material conveyance.

Conveying pipeline: seamless steel pipe or wear-resistant lined pipe, usually with a diameter of 150-600mm.

Spiral: including shaft or shaftless spiral blades, the material can be carbon steel, stainless steel or special alloy.

Drive device: composed of motor, reducer and coupling, can be equipped with variable frequency speed regulation.

Inlet and outlet device: various interface forms are designed according to process requirements.

Supporting components: including hanging bearings, intermediate supports, etc.

The material enters the conveying pipeline through the feed port, generally below or on the side of the equipment, and the spiral blades rotate under the drive of the motor. Due to the shape of the spiral, the material is thrust during the rotation, so that it moves forward along the pipeline and is discharged through the discharge port to complete the entire conveying process.

| LS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery capacity QΦ=0.33 (m³/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| 功率Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m (KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m (KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m (KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m (KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

Tubular Screw Conveyor Equipment is adaptable to a variety of scenarios, including conveying chemical powders, building material granules, grains, and even the food and pharmaceutical industries. It offers anti-contamination sealing and corrosion-resistant materials, meeting the needs of sealed material conveying in various industries.

Mining industry: tubular screw conveyors can transport materials in various forms, whether it is coarse-grained ore just mined from the mine or fine-grained tailings after processing.

Chemical industry: It can meet the strict requirements of the chemical industry for material transportation, including the transportation of corrosive, toxic and explosive materials.

Food and beverage industry: Made of food-grade materials, its smooth inner surface and good sealing can prevent material contamination. Used to transport various food raw materials, such as grains, powders and small-sized food products.

Building materials industry: used to transport building materials such as cement, sand, and gravel. Its large-capacity conveying capacity and ability to adapt to materials of different particle sizes make it an indispensable part of the production line of building materials factories.

Dahan Machinery has focused on the research and development and manufacturing of tubular screw conveyors for more than 10 years. Its products cover a variety of models such as shaft/shaftless, horizontal/inclined/vertical, and are widely used in chemical, environmental protection, food and other industries. The company has a modern production base, has passed ISO9001 certification, and provides a variety of material options such as carbon steel, stainless steel, wear-resistant lining, etc., and supports non-standard customization. With precision manufacturing, stable performance, and perfect after-sales, if you need it, please contact us!

Tubular Screw Conveyor Equipment has become an important part of modern industrial production. With the continuous advancement of technology and the increasing diversification of industrial needs, tubular screw conveyor equipment will continue to develop and innovate, providing faster, more stable and more intelligent material conveying solutions for various industries.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!