Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

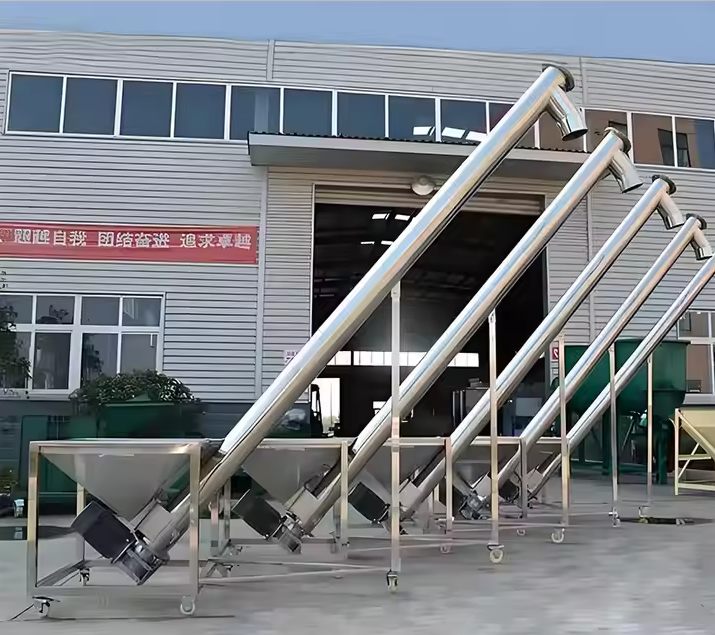

Powder Screw Feeder Conveyor can convey any powder to the packaging machine and food processing destination. It adopts the principle of spiral feeding and can convey in an inclined, horizontal or vertical manner. It is suitable for different scenarios and is made of stainless steel and carbon steel.

The Powder Screw Feeder Conveyor can flexibly change the installation angle and conveying direction. The conveyors we provide are mainly divided into three types: horizontal conveying, inclined conveying and vertical conveying.

Horizontal screw conveyor: Installation angle: 0°~15° (close to horizontal), suitable for short-distance conveying, uniform feeding, mixing and stirring, usually using U-shaped trough or tubular structure, easy to maintain, suitable for powders with good fluidity.

Inclined screw conveyor: Installation angle: 15°~45° (some models can reach 60°), suitable for powder conveying that requires a certain lifting height, such as from the ground to the silo, mixer feeding, etc. Compared with horizontal + vertical combined conveying, the inclined structure is more compact. It can convey slightly agglomerated powders (such as premixes, feed additives).

Vertical screw conveyor installation angle: 90° (completely vertical), suitable for powder conveying that requires a large height lift (such as tower production lines, high-rise silo feeding). Suitable for factory layouts with limited space, the pipeline design can prevent powder from flying, meeting environmental protection requirements.

| LS Model | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX Model | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Rotating speed(r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Throughput QΦ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| Power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Rotating speed(r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Throughput QΦ=0.33(m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Rotating speed(r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Throughput QΦ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Rotating speed(r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Throughput QΦ=0.33(m3/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

The Powder Screw Feeder Conveyor uses a rotating screw shaft to drive blades, propelling powder materials axially under the influence of gravity and friction. Once loaded into a fixed trough, the material does not rotate with the screw due to its own gravity and friction with the trough walls. Instead, it slides forward solely under the axial component of the blades' normal thrust, achieving continuous conveying.

Powder Screw Feeder Conveyor consists of core components such as drive unit, screw shaft, screw blades, casing, feed port, discharge port and bearing system. The powder is continuously transported along the axial direction through the rotation of the screw shaft.

Spiral shaft: It is the core component of the conveyor, runs through the entire length of the conveyor, and plays the main role in conveying materials.

Spiral blade: It is fixed on the spiral shaft and is the key component for pushing the material along the axis direction of the conveyor.

Bearing: It is used to support and fix the spiral shaft, reduce friction, and ensure the smooth rotation of the spiral shaft.

Transmission device: It is usually composed of a motor, a reducer, etc., which is used to drive the rotation of the spiral shaft.

Support frame: used to support the structure of the entire conveyor to ensure the stability and safety of the conveyor during operation.

Feed port and discharge port: used for the entry and exit of materials. The feed port is usually located at one end of the conveyor, while the discharge port is located at the other end, which facilitates the smooth transportation of materials.

As a common device for conveying powder materials, the Powder Screw Feeder Conveyor features a sealed structure to prevent dust leakage and a variable pitch design to solve the problem of material slugging. It is suitable for continuous powder batching in a variety of industries.

Compact Structure and Small Footprint: Flexible and adaptable to various space layouts, it can be easily installed and used in both small workshops and complex production lines.

Stable and Adjustable Conveying Capacity: By adjusting the screw shaft speed, the powder conveying volume can be precisely controlled to meet diverse production needs. When used with a silo at the inlet of a tubular conveyor, it provides continuous and stable feeding, preventing material interruptions or accumulation, and ensuring continuous production.

Excellent Sealing Performance: Effectively prevents powder leakage, reduces environmental pollution, ensures a clean working environment, and minimizes material loss.

Customizable: A silo can be added to the feed port for convenient operation. We also support multi-point unloading, allowing multiple outlets to be added to the pipe.

Powder Screw Feeder Conveyor is widely used in many fields due to its advantages of fast transportation and airtight dust prevention. It is used to transport cement and lime powder in the building materials industry, add pigments and additives in the chemical industry, and transport flour and starch in the food industry, adapting to different working conditions.

Building materials industry: powder screw feeder is often used to transport raw materials such as cement and limestone powder to realize the automated feeding process and improve production efficiency.

Food processing: spiral feeder conveyors are used to convey powdered food raw materials such as flour, powdered sugar, and grains to ensure continuous feeding of food production lines, production efficiency, and food quality.

Chemical manufacturing: powder spiral feeder conveyors are often used to convey chemical raw materials or finished powders, such as granular fertilizers, plastic granules, etc., to meet the conveying needs of different process flows.

Pharmaceuticals: commonly used to convey pharmaceutical raw material powders or granules to ensure accurate feeding in the pharmaceutical production process and ensure production quality and safety.

Agricultural field: can be used to convey granular agricultural products such as feed and seeds to improve the efficiency of feed processing and seed processing.

Other industries: powder spiral feeder conveyors are also widely used in plastic processing, mining, environmental protection and other industries to convey various types of powdered or granular materials to meet the production needs of different industries.

The selection of a Powder Screw Feeder Conveyor should be determined based on the characteristics of the powder. For powders that easily absorb moisture and agglomerate, choose a model with heating/stirring. For powders that are prone to abrasion, choose a model with wear-resistant liners. For food-grade powders, choose 304 stainless steel to ensure adaptability and conveying stability.

Powders with slight agglomeration (such as feed premix): Choose an inclined screw conveyor (<45°), and add a vibration anti-blocking device if necessary.

Powders with high viscosity/easy adhesion (such as powdered sugar, fish meal): Prioritize horizontal conveying + wear-resistant lining, or use pneumatic conveying instead.

High-height lifting (>10 meters): A vertical screw conveyor must be selected, and ensure that the powder is dry and has good fluidity.

As a manufacturer of Powder Screw Feeder Conveyors, we serve customers in various industries, including food, building materials, and chemicals. We customize 304 stainless steel models for food factories to convey flour and prevent pollution, and we equip building materials factories with wear-resistant liner models to convey quartz sand and reduce wear. We are able to create suitable equipment based on our on-site case experience.

Conveying calcium carbonate powder in the chemical industry: Large chemical companies need to transport calcium carbonate powder from the grinding workshop to the packaging line, with a conveying distance of 25 meters, requiring dust-free and moisture-proof. The U-shaped horizontal screw conveyor (304 stainless steel, fully enclosed structure) has a conveying capacity of 10 tons/hour, a motor power of 5.5kW, is completely enclosed, and the dust overflow rate is <0.1%.

Upgrade of milk powder production line in food industry: The original pneumatic conveying system of the dairy factory has high energy consumption and the milk powder breakage rate exceeds 5%. Customized large-angle screw conveyor (40° tilt, food-grade 316L stainless steel), special low-speed design (60rpm) to reduce milk powder breakage.

Vertical conveying of vitamin premixes in pharmaceutical industry: Vitamin powder needs to be lifted 12 meters to the mixing tank, requiring zero cross contamination. Install shaftless vertical screw conveyor (eliminating the risk of bearing contamination), modular quick-disassembly structure, to meet GMP certification requirements.

Dahan Machinery Manufacturing Co., Ltd. focuses on the research and development and production of powder screw conveying equipment. Relying on its independent core technology, the company has created a full range of screw conveying solutions, covering horizontal, inclined and vertical conveying models, with a processing capacity of 0.5-200 tons/hour, which are widely used in more than 30 industries such as chemical, food, metallurgy, and environmental protection. With customized intelligent manufacturing as the core advantage, for special working conditions such as high temperature, corrosion, and explosion-proof, innovative research and development of high temperature resistant sealing structure (-50℃~850℃), nano anti-corrosion coating and anti-blocking frequency conversion speed regulation technology, the equipment life is increased by more than 50% compared with the industry standard. Passed ISO 9001 quality system certification, key components are precision manufactured by CNC machining centers to ensure operational stability.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!