Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Tubular Shaftless Screw Conveyor uses spiral blades without a central shaft to rotate in a closed tubular casing. Compared with traditional shafted screw conveyors, it makes the conveying space more open and can effectively avoid problems such as blockage and entanglement of materials during the conveying process.

The advantages of tubular Shaftless Screw Conveyor are mainly the following.

No center shaft and zero blockage: No center shaft structure, easy to handle easily entangled materials, such as dewatered sludge and kitchen waste.

Fully enclosed and anti-scattering: The pipeline is fully enclosed to prevent dust, sewage dripping and odor overflow, in line with environmental protection standards.

Different materials are available: 304/316 stainless steel or lined with high molecular polyethylene, suitable for acid, alkali, and oily sludge.

Flexible installation: supports horizontal, inclined (≤30°) or vertical arrangement, adapting to complex site conditions.

Low maintenance: No intermediate bearing, reducing failure points, and maintenance costs are reduced by more than 50% compared with shafted screws.

Sewage treatment: Sludge has the characteristics of high viscosity, high water content, and easy winding. The tubular shaftless screw conveyor can smoothly convey the sludge to the sludge dewatering machine, sludge digestion tank and other equipment with its unique advantages.

Chemical powder: Chemical production often involves the transportation of various powdery, granular, viscous or corrosive materials. The tubular shaftless screw conveyor can adapt to these complex material characteristics and transport raw materials to equipment such as reactors and storage tanks, avoiding safety hazards and economic losses caused by material leakage and equipment corrosion.

Building materials industry: The tubular shaftless screw conveyor can transport powdered cement, lime and other materials from storage silos to mixers, packaging machines and other equipment, and can also transport blocky raw materials to crushers for crushing.

Food and agricultural product processing industry: The tubular shaftless screw conveyor can meet the strict hygiene requirements of the food industry for conveying equipment, ensuring that the materials are not contaminated during the conveying process.

Biomass energy industry: It can convey biomass raw materials such as straw, wood chips, and biogas residue to fermentation tanks, molding machines and other equipment.

The working principle of the tubular shaftless screw conveyor is based on the rotation of the spiral blade to push the material forward. When the drive device is started, it drives the shaftless screw to rotate at high speed in the tubular casing. The rotation of the spiral blade generates an axial thrust, and under the action of this thrust, the material moves along the inner wall of the casing toward the discharge port. During the conveying process, the material's own gravity and the friction between the material and the inner wall of the casing jointly ensure that the material can be transported forward stably without rotating with the spiral blade.

| Model |

Diameter (mm) |

Rated speed (r/min) |

Reference capacity (m³/h) |

Motor power (Kw) |

Admission biggest gradient (o) |

| LS114 | 114 | 84-130 | 0.1-1 | 0.75-18.5 | 0-90 degrees |

| LS133 | 133 | 1-2 | |||

| LS159 | 159 | 3-5 | |||

| LS219 | 219 | 5-15 | |||

| LS245 | 245 | 15-20 | |||

| LS273 | 273 | 20-30 | |||

| LS315 | 315 | 28-40 | |||

| LS400 | 400 | 35-45 | |||

| LS500 | 500 | 45-70 | |||

| LS600 | 600 | 60-100 |

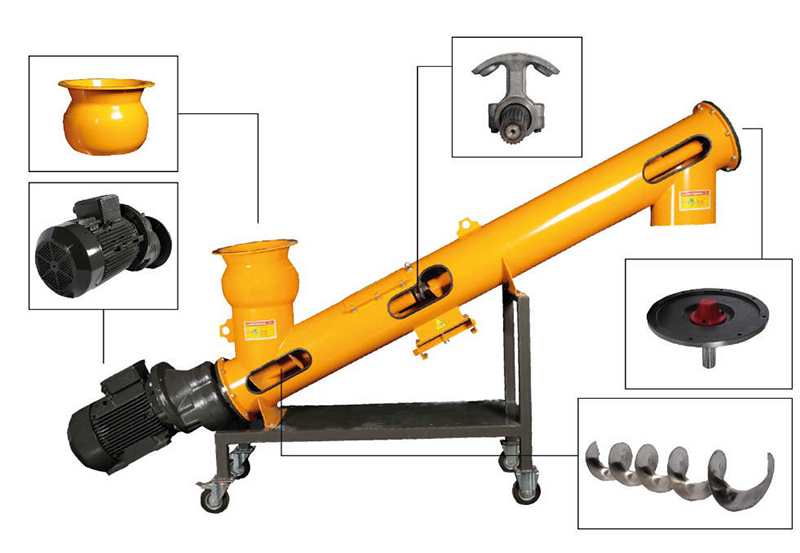

The structure of the tubular shaftless screw conveyor mainly includes the following parts.

Spiral blade: a belt-shaped spiral without a central axis, made of wear-resistant steel or stainless steel to prevent material adhesion.

Conveying pipeline: a circular closed pipe body (carbon steel/stainless steel/wear-resistant liner) to prevent leakage and odor diffusion.

Drive device: a reduction motor + frequency conversion control system, which can adjust the conveying speed and flow rate.

Inlet/outlet: flange connection, suitable for upstream and downstream equipment interfaces.

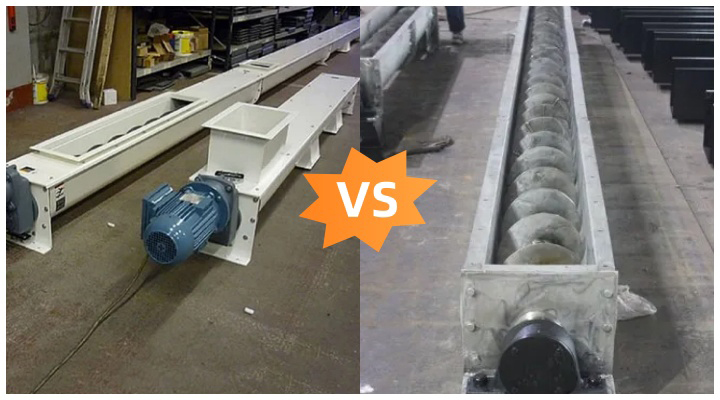

Compared with the U-shaped shaftless screw, the tubular shaftless screw conveyor has the following characteristics

Our tubular shaftless screw conveyor can be customized according to your applicable scenarios, conveying distance, conveying volume and some special needs, giving you a perfect conveying solution.

| Comparison Item | Tubular Shaftless Screw | U-Trough Shaftless Screw |

| Sealing Performance | Fully enclosed, zero leakage | Requires cover plate, minor gap risks |

| Pressure Resistance | Withstands slight internal pressure (e.g., pneumatic conveying) | Limited to atmospheric pressure |

| Space Occupancy | Compact circular pipe, suits narrow spaces | U-shaped trough requires wider installation space |

| Cost | Higher (complex pipe fabrication) | Lower |

Tubular shaftless screw conveyors can convey materials with various characteristics, and their unique design makes them advantageous in dealing with complex materials.

Viscous materials: such as sludge produced by urban sewage treatment plants, this type of material has high viscosity and is easy to stick. Tubular shaftless screw conveyors have no central shaft obstruction and can convey smoothly, ensuring the transfer of sludge from sedimentation tanks to subsequent treatment units in the sewage treatment process.

Materials with high fiber content: Like pulp waste liquid from the papermaking industry, which contains a large amount of fiber, the tubular shaftless screw conveyor can rely on the continuous shaftless screw body to allow the fiber material to move smoothly in the tubular casing to ensure the continuity of the papermaking production process.

Materials containing solid impurities: For example, solid impurities such as plastic bags and branches mixed in during the treatment of domestic waste, and ore fragments and impurity mixtures after mining. The tubular shaftless screw conveyor is not afraid of these solid impurities and can smoothly transport them to the designated location to avoid equipment failure caused by impurity entanglement.

Powdered materials: The fully enclosed tubular casing of the tubular shaftless screw conveyor can effectively prevent the leakage of powdered materials and the flying of dust, ensuring that the conveying process is environmentally friendly and safe, and during the conveying process, the powdered materials will not be conveyed smoothly due to interference from the central axis.

Granular materials: The tubular screw conveyor can use the wide spiral blades and sufficient internal space of the casing to realize the conveying of granular materials, meeting the large-scale material conveying needs of industries such as plastic production and feed processing.

Block materials: such as block gypsum, limestone and other raw materials, the tubular shaftless screw conveyor can adapt to the conveying requirements of block materials and complete the material handling task by reasonably designing the shape, material and conveyor operating parameters of the spiral blades.

When selecting a tubular shaftless screw conveyor, the following factors need to be considered comprehensively.

Characteristics of the conveyed material: Including the viscosity, humidity, particle size, whether it is easy to entangle, corrosiveness, etc. of the material.

Material conveying capacity: How much is the conveying capacity per hour or day, which will be related to the diameter of the conveyor.

Required conveying distance and inclination angle: This data determines the length and installation angle of this conveyor.

Drive mode and motor power: Select a suitable drive device according to the conveying capacity and conveying distance.

Material of casing and spiral blades: Choose appropriate materials according to the corrosiveness and abrasiveness of the material, such as carbon steel, stainless steel, etc.

The tubular shaftless screw conveyor has become an indispensable and important equipment in modern industrial production and material handling with its unique structural design, efficient working principle, excellent performance advantages and wide range of applications.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!