Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Dry Mortar Screw Conveyor is mainly used to convey powdered and granular materials, such as cement, sand, dry mortar, etc. It uses spiral blades to rotate to transport dry mortar or concrete raw materials from one place to another. The design of the spiral blades makes it difficult for materials to be blocked during transportation. It is one of the important conveying equipment for construction sites and mixing stations.

As a special conveying equipment, the main characteristics of dry mortar screw conveyor are as follows

Sturdy and durable: Dry mortar screw conveyor is generally made of carbon steel and stainless steel, which will increase its service life.

Customizable: It can be customized according to different conveying distances, conveying volumes and inclination angles, and is suitable for a variety of construction sites.

Widely used: Dry mortar screw conveyor can also be used for conveying cement, powder, corn, grains and other purposes.

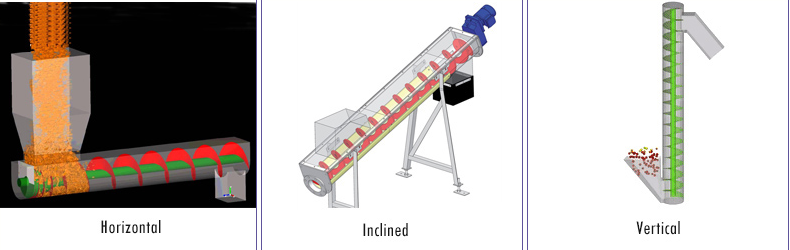

Dry mortar screw conveyors can be classified according to different needs and scenarios in terms of design and use. The following are some common types of dry mortar screw conveyors:

Horizontal screw conveyor: Mainly used for horizontal conveying, suitable for short-distance material conveying, often used in construction sites, concrete mixing plants and other places.

Inclined screw conveyor: Different inclination angles can be set as needed, used for inclined conveying of materials, suitable for situations where the site height difference is large or it needs to be conveyed from one place to another.

Vertical screw conveyor: Mainly used for vertical conveying, can convey materials to higher or lower positions, often used in construction sites or factories.

U-shaped screw conveyor: The conveying pipeline is U-shaped, suitable for conveying materials with high viscosity, preventing material blockage, and used to convey materials such as mortar with high viscosity.

Tube screw conveyor: It has a closed conveying pipeline and is suitable for places that require a clean and dust-proof environment. It is used to convey powdered or granular materials.

Dry mortar screw conveyor uses its unique advantages to make it one of the indispensable equipment in many places. The following are the main application scenarios

Construction site: Dry mortar screw conveyor is often used in construction sites to transport dry mortar to the construction site to improve construction efficiency.

Concrete mixing station: In the concrete mixing station, the dry mortar screw conveyor is used to transport concrete raw materials to ensure the smooth mixing process.

Building material production plant: In the building material production plant, it is used to transport dry powdered raw materials to the production line to achieve automated production.

The motor drives the spiral blade to rotate, so that the dry mortar is continuously transported in the pipeline along the direction of the spiral blade. The design of the spiral blade can make the dry mortar not easy to be blocked during the transportation process, ensuring the stability and continuity of the dry mortar transportation.

As a source factory, Dahan screw conveyor provides customers with customized and high-quality services, and provides you with screw conveyors of different materials, models and diameters. The prices are all ex-factory prices, which can meet any of your conveying needs!

The advantages of dry mortar screw conveyor such as efficient conveying, precise positioning and labor saving make it an ideal choice for handling dry mortar or concrete conveying.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!