Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Sand Gravel Screw Conveyor is specially used to convey granular or powdery materials such as sand, gravel, sand, etc. It has a simple structure and can use the rotation of spiral blades to promote the conveying of sand and gravel particles. It is widely used in construction, mining, concrete mixing plants and other fields, and can convey sand and gravel from point A to point B.

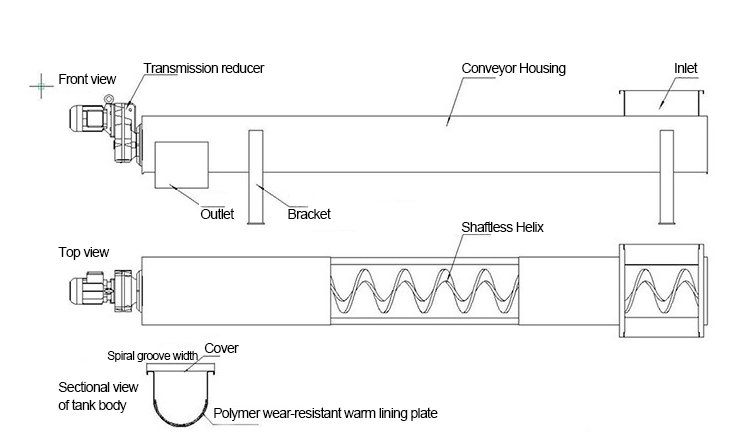

The motor of the sand and gravel screw conveyor drives the spiral shaft to rotate through the reducer, and the spiral blade pushes the sand and gravel from the feed port to the discharge port, and finally realizes the horizontal, inclined or vertical conveying of the material.

Spiral shaft: usually made of high-strength steel, the surface can be specially treated to enhance wear resistance.

Spiral blade: The spiral blade is welded on the spiral shaft, and different blade types can be selected according to the material characteristics.

Conveying trough: The conveying trough is the channel for material flow, usually made of steel plate, with smooth inner wall to reduce friction resistance

Feeding port and discharging port: The feeding port is located at one end of the conveying trough, and the discharging port is located at the other end. The design is flexible and convenient for use with other equipment.

1. It can realize continuous and stable conveying of sand and gravel, and improve the conveying efficiency of sand and gravel work.

2. It can convey a variety of materials such as sand and gravel, crushed stone, sand, etc., suitable for different working conditions.

3. The conveying trough can be completely closed to prevent sand and gravel from leaking and dust pollution during the conveying process.

4. Made of wear-resistant and corrosion-resistant materials, it can ensure that the screw conveyor has certain wear and corrosion resistance during the conveying of sand and gravel.

5. Screw conveyors of different lengths, diameters and angles can be customized according to needs, which can meet the conveying needs of different occasions.

Construction site: It is used to transport sand and gravel particles from one location to another, such as conveying sand and gravel to concrete mixing plants.

Mines: Sand and gravel screw conveyors can be used to transport granular materials such as ore and slag to crushers, screens and other equipment.

Cement plants: In the cement production process, sand and gravel screw conveyors can be used to transport raw material particles to grinding equipment or sintering equipment.

Choosing a sand and gravel screw conveyor that suits you needs to consider multiple factors, including material properties, transportation requirements, site conditions and budget.

1. Clarify material characteristics

Particle size: Materials with larger particle sizes require stronger conveying capacity, so choose a screw conveyor with a larger blade spacing.

Humidity: Wet materials are easy to adhere, so you need to choose equipment that is easy to clean or add anti-sticking design.

Corrosiveness: If the material is corrosive, choose a conveyor made of stainless steel.

2. Determine the conveying requirements

Conveying capacity: Determine the amount of material that needs to be conveyed per hour (tons/hour) based on production needs.

Conveying distance and angle: Horizontal conveying is suitable for short-distance conveying, and standard screw conveyors are selected. Inclined conveying selects suitable equipment according to the inclination angle (usually 0°-45°). Vertical conveying is generally suitable for conveying sand and gravel from the ground to the carriage or storage bin.

3. Consider site conditions: Measure the length, width and height of the installation site, and select equipment of appropriate size. If space is limited, select a compact screw conveyor.

4.Environmental conditions: If the working environment is humid, dusty or corrosive, select equipment with high protection level and corrosion resistance.

As a mechanical equipment specially used for conveying sand, gravel and sand, the main functions of the sand and gravel screw conveyor include the following aspects:

Continuous conveying: It can realize continuous and stable material conveying to ensure the smoothness of the production process.

Large-capacity conveying: It can convey tens to hundreds of tons of sand and gravel materials per hour to meet the needs of large-scale production.

Multi-angle conveying: It can convey horizontally, inclined and vertically, and can adapt to different types of sand and gravel conveying scenarios.

Able to prevent sand and gravel from scattering: The conveying trough can be completely closed to prevent sand and gravel from scattering during the conveying process.

The sand and gravel screw conveyor has become an indispensable equipment in the sand and gravel conveying process due to its high efficiency, reliability and versatility. Whether it is to improve production efficiency or reduce labor costs, it can bring significant value to the enterprise.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!