Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

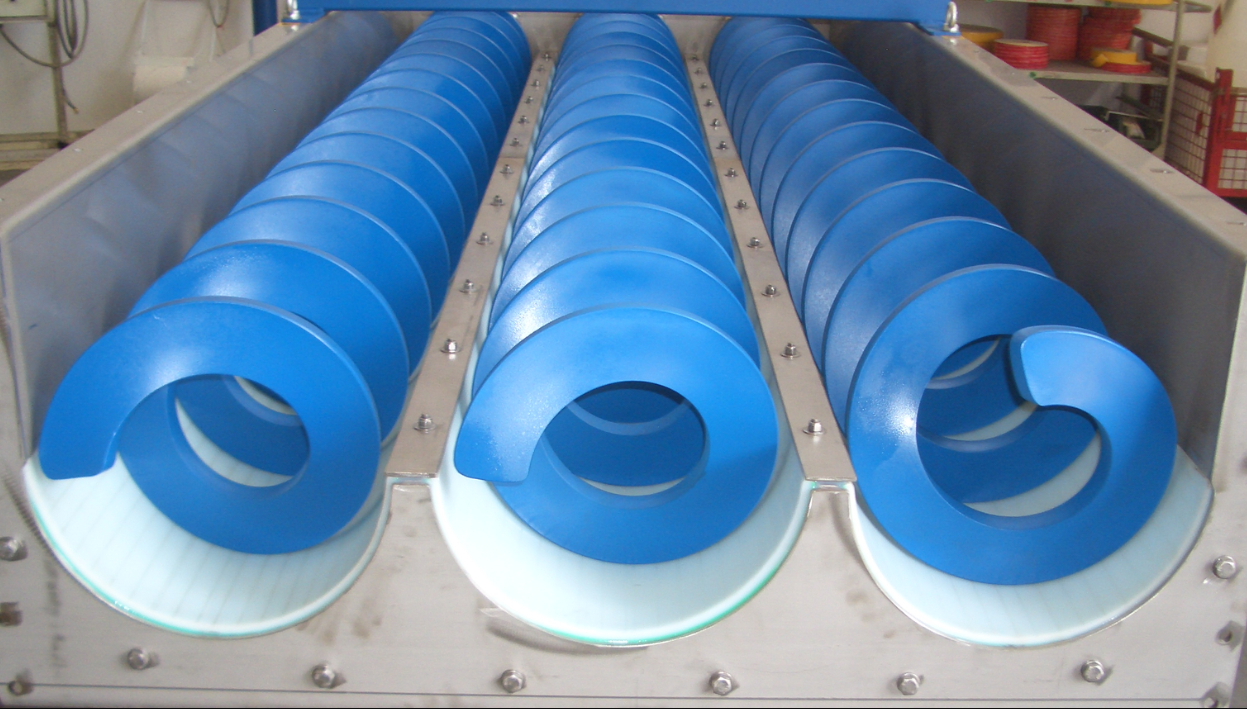

Clay Shaftless Screw Conveyor is a device for conveying clay. It pushes the clay along the spiral groove of the conveyor through the rotation of the spiral blade to complete the transfer of the clay processing. The device adopts a shaftless design to prevent the clay from adhering and clogging in the conveying pipeline. It can efficiently and stably convey clay materials and improve production efficiency.

The clay Shaftless Screw Conveyor drives the spiral blade to rotate through the motor. When the clay enters the trough, the rotating spiral blade pushes the clay forward, just like the screw turns forward in the nut, except that the "nut" here is a fixed trough. Under the continuous push of the spiral blade, the clay is gradually conveyed from the feed port to the discharge port to realize the transfer of materials.

Applicable to different scenarios: It can complete clay transportation in different scenarios.

Automatic operation: The whole machine adopts full automatic

Reduce adhesion problem: Clay usually contains high moisture, which makes transportation difficult. Shaftless screw conveyor can adapt to this characteristic.

Convey different types of clay: Some clay is in strip or flake form and is easy to entangle. Shaftless screw conveyor can also effectively convey such materials.

Long conveying distance: It can convey clay to a longer distance to meet the requirements of production layout.

1. Solve the problem of clay winding and clogging: Traditional screw conveyors have a central shaft, and clay is easy to entangle on the shaft, causing blockage and affecting the conveying efficiency. The clay shaftless screw conveyor adopts a centerless design, which fundamentally solves this problem.

2. Special materials reduce adhesion: The use of special materials and surface treatments, such as Teflon coating, surface polishing, etc., can reduce the adhesion of clay and improve the conveying efficiency.

3. Easily deal with high-water content clay: Clay shaftless screw conveyor can realize the conveying of high-water content clay. Its shaftless design and special material make it difficult for clay to adhere and clog during transportation.

4. Simple maintenance without center shaft: The shaftless screw conveyor has a simple structure and is easy to maintain and maintain. Since there is no center shaft, the problems of winding and clogging are reduced, thereby reducing maintenance costs.

The clay shaftless screw conveyor has a variety of application scenarios when handling sticky materials such as clay, including but not limited to the following aspects:

Ceramic clay transportation: In the ceramic manufacturing process, clay needs to be transported to the workstation of ceramic raw materials to ensure the continuous production of ceramic items.

Brick and tile manufacturing: Clay shaftless screw conveyor is used to transport clay to mixers, molding machines and other equipment to ensure the production efficiency and quality of building materials.

Ceramic brick production: In the ceramic brick manufacturing process, clay shaftless screw conveyor is used to transport clay raw materials to the pressing machine, so that clay can be evenly pressed into brick blanks, improving production efficiency.

Mining and ore processing: It is used to transport ore containing muddy and sticky materials to crushers, screening machines and other equipment to help process and sort ore raw materials.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 | ||||||

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 | ||||||

| Outer diameter(mm) | 180 | 219 | 273 | 354 | 402 | 500 | ||||||

| Incline degree(a) | 0。-30。 | 0。-30。 | 0。-30。 | 0。-30。 | 0。-30。 | 0。-30。 | ||||||

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 | ||||||

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 | ||||||

| Motor | Model | L≤7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 | ||||

|

Power

kW

|

L≤7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |||||

| Model | L≤7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |||||

|

Power

kW

|

L≤7 | 2.2 | 3 | 4 | 7.5 | 15 |

1 5Notes : The parameter above is just for reference, Model please inquiry us directly. We

accept customization.

|

|||||

Teflon coating: Coating non-stick materials such as Teflon on the inner wall of the conveying trough to reduce material adhesion.

Surface polishing: Polishing the inner wall of the conveying trough to make its surface smooth and reduce material adhesion.

Installing vibrator: Install a vibrating device on the conveying trough to prevent the material from adhering during transportation through vibration.

Clay shaftless screw conveyor is an ideal choice for conveying sticky materials such as clay. It has the advantages of simple structure, strong conveying capacity and good sealing. When selecting and using clay screw conveyor, you can choose suitable conveying equipment based on your conveying volume and conveying distance.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!